UPDATE!!! The content below is now out of date and has been replaced with the Bay Area Mask Making and Distribution Project

Goal: Make PPE to FREE up the dwindling supply of N95 Masks for Front Line Healthcare Workers

This started with the idea to just do something to help.

3-20-20

I have gotten the okay from Stone Mountain and Daughters to purchase cotton at $5 per yard for making masks.(No Contact Purchase)

Unfortunately, I am broke AF as most of my income is drying up in these trying times. But I have time and skills. So makin’ masks is what is going on.

I am asking for ya’lls help to:

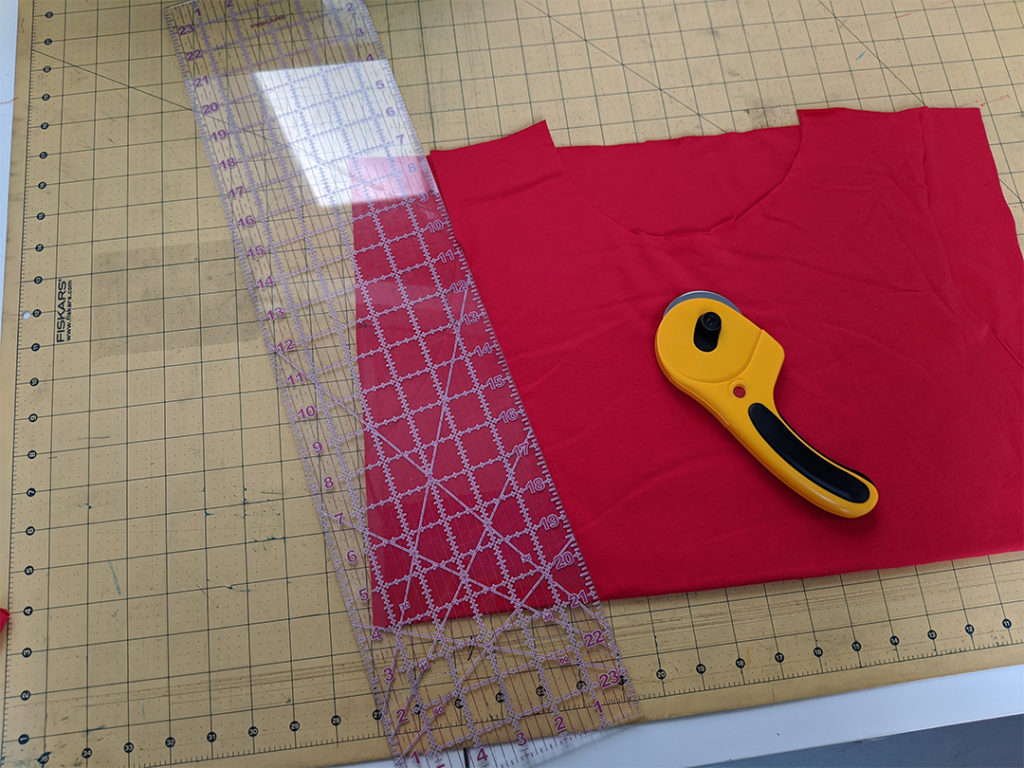

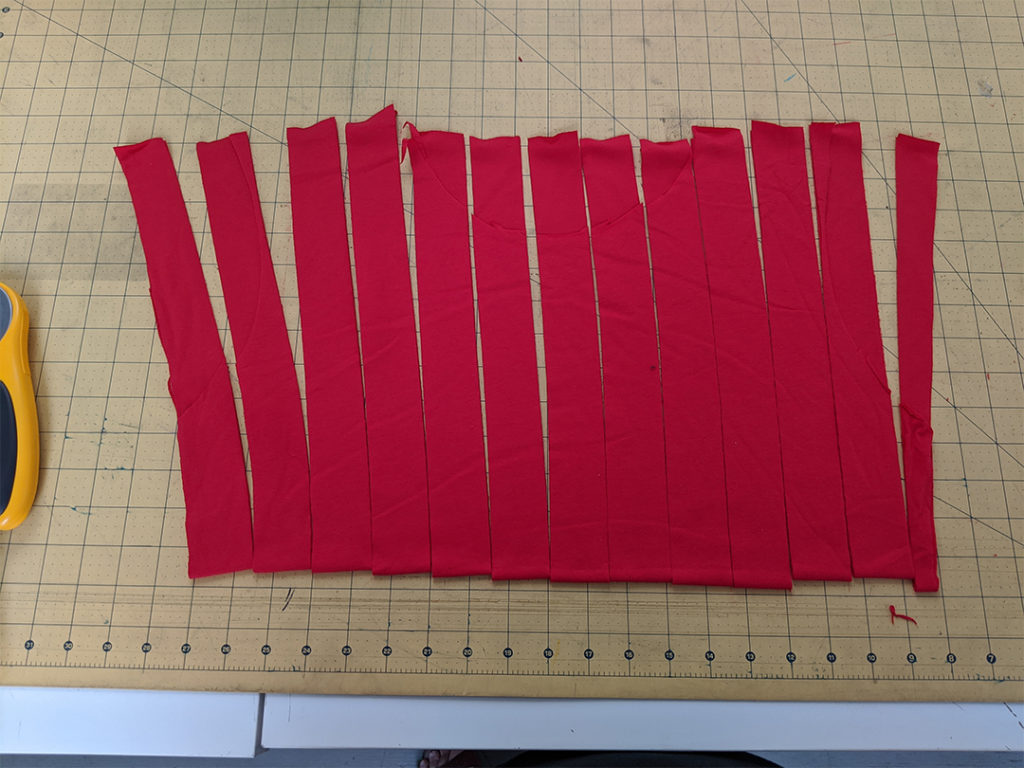

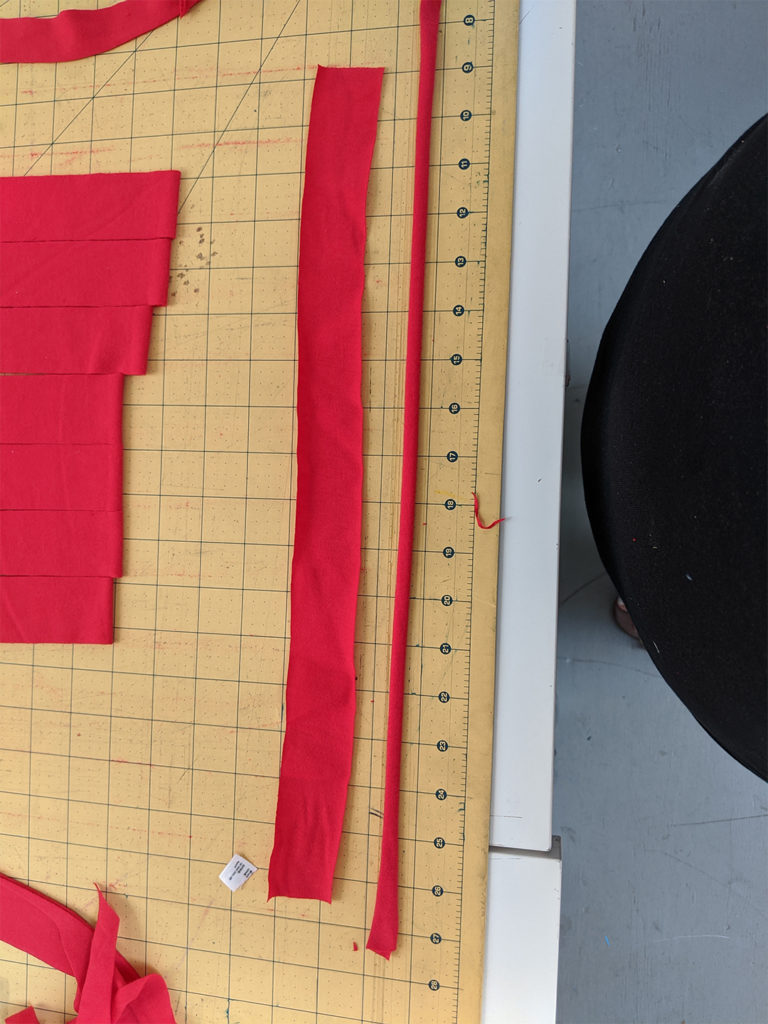

- 1) Buy Mask Fabric

- 2) Sew Masks (if you are the sewing type) once the fabric is acquired.

- 3) Collect information on the right place to donate them (aka facilities that can launder them to ensure they are safe before use)

We can do this all no contact and provide them to healthcare facilities to launder to standards and use as they see fit. While this may not directly fix the mask shortage as sewn masks are not as good as N95’s they will help in places like cancer wards, elder care facilities, blood collection labs and so on.

Please paypal paypal.me/craftyavenger

$5 = materials for approx. 12 masks

Update!

For folks wanting to join in the mask making Additional resources are being collected and will roll out today and tomorrow including patterns and standards. For the near term here are a few guidelines:

- Anybody who is feeling sick in any way, even if it just might be hay fever, please do not engaging in mask making. There are other ways to help.

- Anybody with suggestions on Bay Area organizations to contact for distribution please comment or email [email protected]

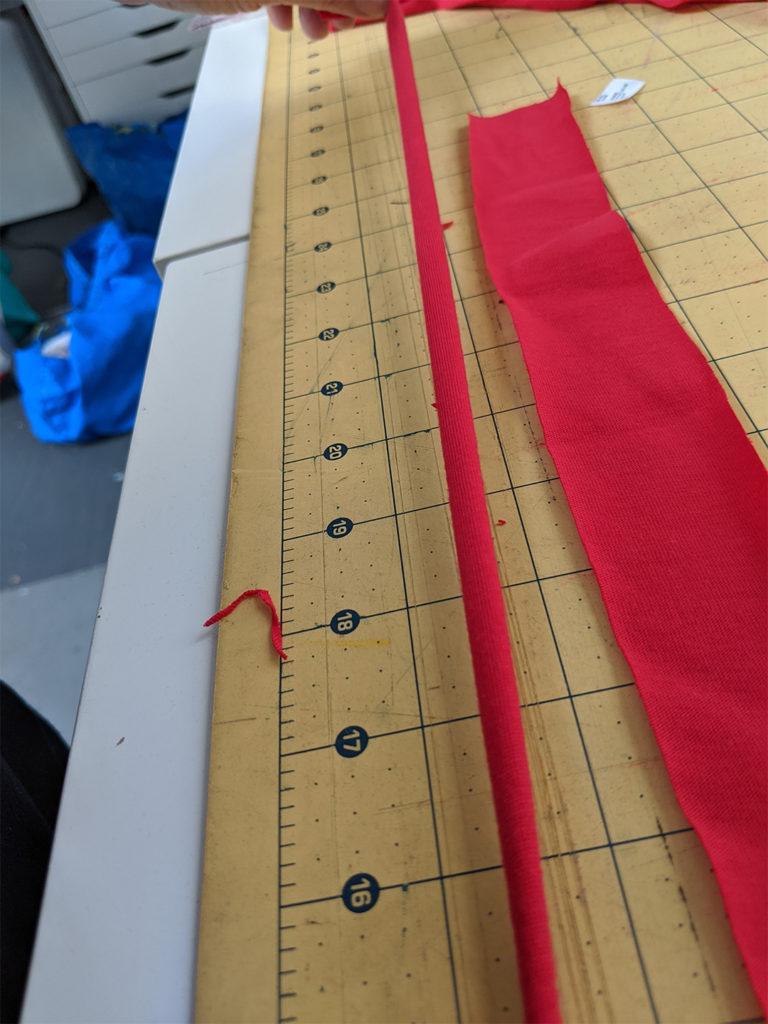

- Elastic is in short supply. If you have .25″ elastic sources please email about those too.

Disclaimer: These masks do not replace N95 masks. But are better than nothing and when made and worn correctly can get 65% – 85% of the particulate. This effort is to provide the most vulnerable in our population an option as shortages mean then have no other. This will free up proper PPE for Healthcare workers… because without them nothing else will matter. More from the CDC

Hugs. Stay Safe Out there.